Every service call starts with a multi‑step diagnostic, not just a quick visual glance: light‑probe microscopy - we run a fiber‑optic scope across the impact site to reveal hairline fractures that can’t be seen with the naked eye; crack‑trajectory mapping- proprietary software predicts how far (and how fast) a chip might spread under Roswell’s daily 20‑to‑40 °F temperature swings; moisture intrusion test - we measure trapped humidity inside the break to determine whether the glass can be vacuum‑dried for repair or needs full replacement.By the end of this assessment, you’ll see real‑time photos and data visualizations on a tablet, so our recommendation - repair or replacement - makes perfect sense.

Windshield repair and replacement in Roswell, GA

Looking for reliable windshield repair Roswell residents can count on? Glass Inc is the local, auto‑glass company trusted by commuters, families, and rideshare drivers across North Fulton. We understand how a single pebble kicked up on GA‑400 can shatter your morning routine - one moment you’re cruising toward Canton Street for coffee, the next you’re squinting through a spiderweb crack. That’s why our Roswell team combines decades of technical know‑how with same‑day scheduling to restore your windshield - and your peace of mind - without disrupting your day. Our certified technicians arrive fully equipped with climate‑controlled resin systems, fracture assessment tools, and a complete inventory of precision‑cut glass. Whether your vehicle is a daily‑driven sedan, a SUV, or an EV loaded with cameras and sensors, we bring the tools and expertise needed to get the job done right the first time. What sets us apart? Transparent communication every step of the way. From the moment you call or book online, we walk you through the process, explain the science behind repair versus replacement, and spell out costs up front - no surprises, no hidden fees. Best of all, you choose the service style that fits your life: stop by our shop for the fastest curing times, or let our mobile crew come to your driveway, office garage, and etc. Either way, you’ll drive away with crystal‑clear visibility, renewed structural integrity, and the confidence that your vehicle is ready for whatever Georgia roads throw its way next. Ready to reclaim a flawless view of the road? Tap the button below to secure your preferred appointment slot - our calendar fills quickly during peak pollen and construction seasons!

Why Roswell drivers choose Glass Inc

A clear windshield is your single largest field‑of‑view safety component. Glass Inc has spent 68+ years mastering auto‑glass best practices across metro Atlanta, and our Roswell team brings that expertise straight to your driveway or office parking deck. We emphasize: precision inspections - digital magnification and crack‑trajectory analysis help us predict whether a chip will spread or if full glass replacement is the smarter option; high performance resins and glass - only products that pass rigorous impact, clarity, and temperature‑cycle tests reach your vehicle; mobile convenience - our vans carry climate‑controlled resin kits, moisture barriers, and suction‑cup extraction rigs to handle complex installations curbside; transparent pricing - up‑front quotes and clear explanations ensure no surprises at checkout.

Comprehensive damage assessment

Premium repair materials

Our resin and adhesive lineup isn’t off‑the‑shelf - it’s hand‑picked after lab testing for Georgia‑specific conditions: optical‑grade clarity - the cured resin matches your factory glass’s refractive index, eliminating distortion and rainbow glare at night; dynamic flexibility - formulated to expand and contract from ‑20 °F winter mornings to 120 °F dashboard heat without losing bond strength; UV‑shield additives - embedded stabilizers block yellowing and cloudiness, keeping the repair nearly invisible for years; acoustic damping - an added elastomer layer absorbs vibration, subtly reducing wind noise at highway speeds. The result? A repair that maintains visibility, resists future cracking, and even boosts cabin quietness.

Expert craftsmanship

Tools matter, but technician skill is important. Each Glass Inc tech completes over 1,200 supervised hours before leading a job: debris extraction - pressurized dry air and carbide micro‑drills clear out crushed glass dust, ensuring the resin bonds to clean surfaces; vacuum‑seal bridge - a precision fixture pulls air out of the break while drawing resin deep into the crack’s tiniest capillaries; UV‑LED cure grid - our lamps bathe the area in calibrated 365 nm light, fully polymerizing the resin in 60 seconds without overheating surrounding tint strips; surface polish and optical blending - a diamond slurry removes any residual bumps, then a final polish feathers the repair edge into surrounding glass for an almost invisible finish. This careful approach restores structural integrity and aesthetic perfection - crucial if you’re trading in or returning a leased vehicle.

Safety‑first final check

Before handing back the keys, we perform a four‑point validation to guarantee the job’s longevity and your safety: refraction‑variance scan- a laser gauge checks light bend across the repair to ensure zero distortion in your forward field of view; hydrostatic leak test - we simulate a heavy Roswell downpour with a pressurized water curtain, confirming no seepage through seals or cowl panel; stress‑load flex**: Gentle frame torsion replicates pothole hits on GA‑400; sensors monitor for resin micro‑fracture or bond failure. Only when all metrics hit our benchmark do we call the job complete - so you can drive away confident your windshield will handle the next bump, storm, or sudden stop.

Windshield repair Roswell trusts

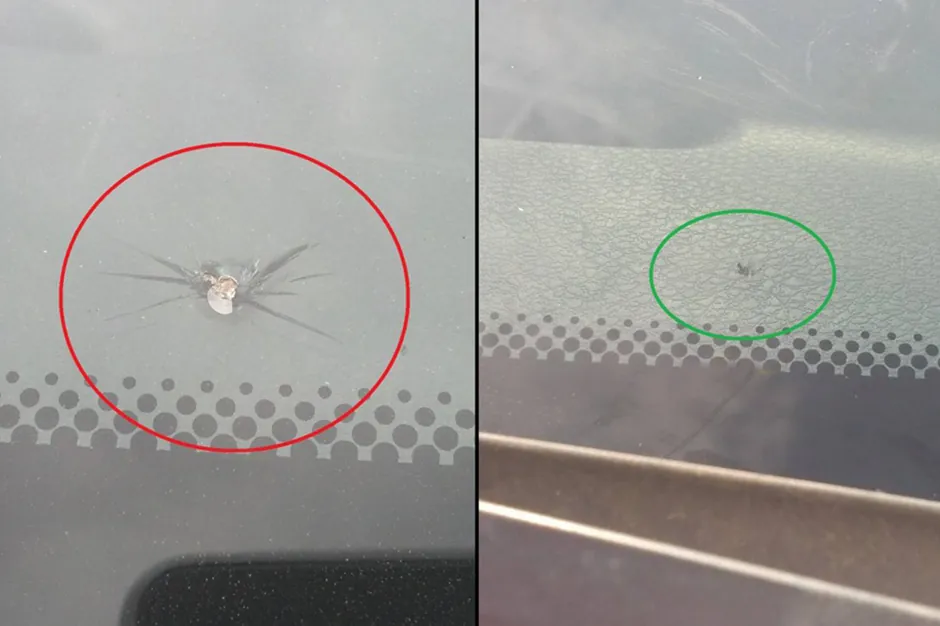

Even a pebble flung at 65 mph can drill a crater deep enough to scatter light and strain your windshield’s lamination. Once that starter chip appears, Georgia’s steamy afternoons and cool evening showers expand and contract the glass, turning a pinhole into a sprawling fracture almost overnight. Glass Inc repairs halt that chain reaction in its tracks. After isolating the damage with protective film, our techs vacuum‑extract debris, inject an optically clear, UV‑curing resin, and pulse‑cure it in 60‑second intervals to eliminate micro‑bubbles. The entire procedure - assessment, prep, cure, and polish - wraps up in about 45 minutes. You can squeeze it in before work, between errands, or while grabbing brunch on Canton Street. The payoff is two‑fold: up to 90 % of original transparency returns, so glare and halo effects disappear, and the structural bond between the inner and outer glass layers is re‑established, ensuring your windshield stays intact during sudden stops or air‑bag deployment. Add in our detailed post‑repair clarity checks, and you’re back on the road - kids safely buckled for Roswell North Elementary pickup - without the cost or downtime of a full replacement.

Full windshield replacement done right

When chips creep into the driver’s direct line of sight, spider beyond three inches, or fracture all the way to the glass edge, a replacement becomes the only route to uncompromised safety. At Glass Inc, we treat full replacements like precision surgery, not a quick swap‑and‑go job. First, trim panels, wiper arms, and cowl grids are removed, then the damaged pane is extracted with a robotic suction‑cup rig that prevents torque from warping delicate A‑pillars. Next, the pinch‑weld is cleaned down to factory primer and brushed with fresh bonding agent to guarantee a watertight seal. We stock high‑clarity glass cut to exact manufacturer specs for everything from daily‑driver sedans to camera‑equipped EVs and lane‑keeping SUVs. During installation, laser‑leveled guide blocks ensure perfect alignment, eliminating wind hiss at highway speeds. Integrated sensor housings - rain, light, lane cameras - are transferred with antistatic gloves to prevent dust contamination. Finally, the glass is seated with uniform pressure and cure‑monitored in real time. You roll out with a windshield that meets strict visibility standards, resists Roswell’s punishing UV index, and looks as pristine as the day your vehicle left the showroom.

Mobile auto‑glass service anywhere in Roswell

Skip the shop and reclaim your schedule. Our climate‑controlled mobile units cover every corner of Roswell - from historic homes off Mimosa Boulevard to bustling office parks on Holcomb Bridge Road. Each van carries portable power inverters, canopy umbrellas for sudden downpours, industrial vacuums to capture glass shards, and a full inventory of glass and resin matched to your vehicle’s VIN. Booking is easy: choose a one‑hour arrival window online or by phone, receive a text when the technician is on the way, and track their ETA in real time. On site, we cordon off the workspace with soft‑edge fender guards, protect your dash with lint‑free covers, and complete the same multi‑point inspection, repair, or replacement process offered in‑shop - right in your driveway, parking deck, or even the Big Creek Greenway trailhead lot. Once the job is done, we run a hydrostatic leak test, sweep the area for hidden shards, and email your digital service report with before‑and‑after photos. No commuting, no waiting room - just seamless, professional auto‑glass care delivered where and when you need it most.

Windshield Service FAQs - Roswell

How much does windshield replacement cost in Roswell?

Windshield replacement in Roswell typically ranges from $199 to $500+ depending on your vehicle make and model, glass type (OEM vs. aftermarket), and features like ADAS cameras or rain sensors. Most comprehensive insurance policies cover windshield replacement with $0 deductible in Georgia. Glass Inc provides free quotes and handles insurance billing directly. Call (404) 873-6991 for pricing specific to your vehicle.

Do you offer same-day windshield service in Roswell?

Yes, Glass Inc offers same-day windshield repair and replacement throughout Roswell. With over 1,000 windshields in stock, we can service most vehicles immediately. Our mobile units serve all Roswell areas including Historic Roswell, Holcomb Bridge Road, GA-400 corridor, East Roswell, and Alpharetta Highway areas. Call early in the day for best same-day availability.

Can you come to my Roswell home or workplace?

Absolutely. Our mobile windshield service comes directly to your location anywhere in Roswell - your home, office, or any convenient location. We regularly service the Historic Canton Street area, office parks along Holcomb Bridge, homes near Big Creek Greenway, and throughout all Roswell neighborhoods. Our mobile units provide shop-quality service with zero disruption to your schedule.

Do you handle ADAS calibration in Roswell?

Yes, Glass Inc provides ADAS calibration for all vehicle makes. After windshield replacement, vehicles with lane departure warning, adaptive cruise control, or automatic emergency braking require camera recalibration. Our mobile units carry calibration equipment for dynamic calibration. Some vehicles require static calibration at our facility. We advise on requirements when you schedule.

Is windshield service covered by insurance in Roswell?

Most comprehensive auto insurance policies cover windshield repair and replacement. Many Georgia policies include $0 deductible for windshield claims. Glass Inc works with all major insurers including State Farm, GEICO, Progressive, Allstate, and Liberty Mutual. We handle all paperwork and bill your insurance directly - most Roswell customers pay nothing out-of-pocket.

Not sure if your windshield can be repaired?

Take our quick quiz to get an initial assessment. Or use our FREE VIN Lookup tool to find your exact windshield part number.

Windshield Damage Assessment

Loading assessment quiz...

Restore crystal‑clear vision today

Ready to fix that chip - or swap the entire windshield - without the headache? Our team is on standby. Call now or book online and reclaim a clear, secure view of Roswell’s roads.

Request Your Free Estimate- Phone: (404) 873-6991

- Address: 510 Glen Iris Dr NE, Atlanta, GA 30308